Problem

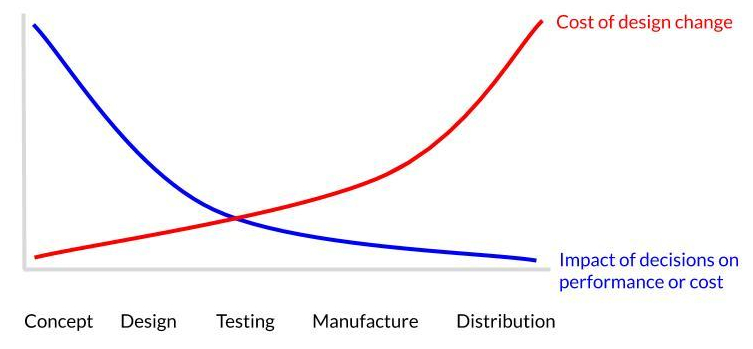

The first phase of engineering product development is concept design, when a broad outline of the function, form and performance is defined. The decisions made at this stage are the most crucial for overall success as they have the largest impact on cost and performance. Modification to a concept later in the development cycle requires redesign work and manufacturing of new parts, both of which extend the schedule and increase costs.

The more complex a product is the more likely it is a slight variation of a current design; thus, only slight improvements are achievable. Concept iterations have to be completed in series between different specialist groups, as each have their own methods and software. Exploring radical concepts can provide huge improvements when the interactions between the disciplines are harnessed, but a new method to do this is required.

Solution

The EvolvedForm software explores many different solutions concurrently to determine the optimal concept, based on a user-defined goal, that may never have been explored otherwise. It builds on current state-of-the-art design technologies:

- Topology optimization finds the most efficient design by removing material, thereby creating holes in a part. Due to mathematical limitations, these results cannot be produced directly and their interpretations can be suboptimal.

- Shape optimization improves on the boundary of a part based on the defined number of holes but is computationally very expensive.

- Generative design is a machine learning algorithm that controls the inputs to a topology optimization subroutine, solving multiple variations concurrently to determine the best design.

Current software is restricted to finding the optimal solution in a single engineering discipline – structural design; therefore, they cannot be used in conceptual design in which the interactions between the discipline need to be understood. These techniques are beneficial later in the design cycle but the impact is greatly diminished.

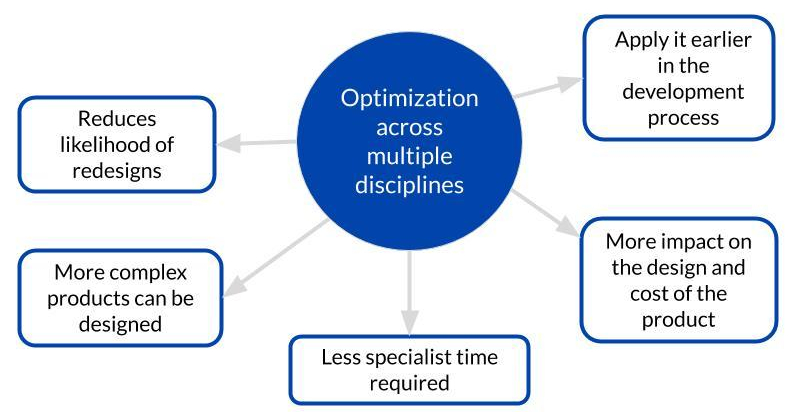

EvolvedForm expands on these technologies in two notable ways: it solves multiple disciplines concurrently and simultaneously solves the topology and shape problems. As it is multi-disciplinary, it is applicable early in the development process with more impact on the product’s performance and cost, and less likely to require redesign. This also has the benefit of necessitating less specialist time, as part of their work is done by the software. As the program integrates topology and shape optimization, the resulting designs do not need interpretation and will be optimal.